Included in collection: Business Management

Operations Management - Lean and Agile Lecture

1.0 Introduction

This chapter focuses on the concepts of lean and agile within the context of operations management. It addresses related aspects such as Just-In-Time (JIT), kaizen, and six Sigma, as well as contemporary interpretations such as leagile. All of these terms, approaches, and techniques collectively refer to the ideal of improving the efficiency of organisational operations. Although they are often used interchangeably, they each have distinct characteristics and some are better suited to particular types of organisation or operational process than others. During this chapter we will examine each of these concepts and their similarities and differences, as well as providing examples of them in operations practice. As alluded to in the previous chapter, the overriding principle of operations management is to make an organisation overall more efficient, and therefore part of this discussion will also include acknowledgement of the need for trade-off decisions. Sometimes, these trade-off decisions must be taken at a senior executive or strategic level if there is an unexpectedly high risk associated with operating in a true lean fashion. It is the role of every operations manager to consider the direct and indirect implications of increasing operational efficiency, and the tools explained in this chapter assist in the process.

2.0 Understanding the Concepts

2.1 Lean

In principle, ‘lean’ is a straightforward concept which can be understood to mean the elimination of any waste in organisational processes. The overarching principle is to improve operations such that they become quicker, more reliable, produce higher quality products and services more consistently, and at a lower price. What is immediately obvious is that this directly contradicts with detail of the previous chapter which recognises trade-offs between quality and cost. Lean is perhaps better understood therefore, as a mind-set or philosophy, and one which is achieved over time rather than as an instantaneous outcome.

2.2 Just in Time (JIT)

The means to achieve a lean state of mind, then organisational operations are most readily achieved with reference to the concept of Just in Time (JIT), which is described as follows.

“JIT is a disciplined approach to improving overall productivity and eliminating waste. It provides for cost-effective production and delivery, of the right quantity of parts of the right quality and at the right time and place, using the minimum amount of facilities, equipment, materials and human resources. JIT is dependent on the balance between supply flexibility and the users’ flexibility. It is accomplished through the allocation of elements required, total employee involvement, and teamwork. A key philosophy of JIT is simplification”

- (Slack, Brandon-Jones & Johnson, 2013).

To simplify this detailed explanation, JIT can therefore be understood as “the ability to meet demand instantaneously with perfect quality and no waste”. (Slack et al., 2010, p.520).

What is key is to recognise that JIT is a continuous and evolving philosophy, a state of ongoing organisational improvement, which requires involvement from every employee from the boardroom down to the shop floor, and from the shop floor back to the boardroom. JIT is not a set of rules or processes to be applied with the expectation of immediate results. Moreover, as the organisation improves as a result of implementing JIT principles, the standards and expectations will also rise, creating a situation of continuous incremental improvement.

2.3 Agile

Agile principles within the concept of operations management refer to the capacity of an organisation respond quickly and effectively to management information or business intelligence, and make appropriate decisions on this basis. It is seldom the case that organisational operations have smooth demand flow because different people want different things at different times, and therefore it is important for organisations to be able to react to a potentially anticipate changes in markets or operational circumstances. Contemporary examples include responding to natural disaster which disrupts a supply chain, making it difficult for the organisation to receive its raw materials or component parts. Agile has a close connection to JIT for obvious reasons, as a JIT operational process runs with very little buffer inventory and if there is any disruption to the supply chain, then an organisation that make an agile response is more likely to recover.

Agile principles also provide a conduit between operational processes and tactical and strategical organisational information. Agile refers to the capability of the organisation to respond to unforeseen circumstances, something that is often much easier for small organisations than for large quotations which can have tightly defined processes and procedures. There is yet another trade-off decision, in that well-defined processes and procedures can help to increase the capacity for JIT and lean thinking, but, can inhibit the capacity for agile response. Ideally, being able to marry the two is preferable state of affairs so that the organisation can be as efficient and effective as possible, and also adaptive responding to and anticipating changing circumstances.

Get Help With Your Business Assignment

If you need assistance with writing your assignment, our professional business assignment writing service is here to help!

2.4 Leagile

The juxtaposition of lean and agile principles has given rise to an emergent concept referred to as leagile, which, as can be imagined is a combination of lean and agile. In other words, the capability of an organisation to have tightly defined and therefore lean processes, but still retaining the ability to adapt and respond to changing circumstances. It is an attempt to overcome the inherent contradiction between two opposing schools of thought in respect of the best way for organisations to be efficient and effective. The terminology leagile emerged from supply chain management which is a critical component of operations management, in that without good supply chain management it would be almost impossible for an organisation to engage with JIT principles. Those in the field of supply chain however recognise the risks and potential significant costs associated with the collapse disruption of a JIT supply chain, which gives rise to the idea of leagile.

Leagile relies heavily on regular and frequent communication between supply chain partners, which will include the client organisation and also extensive use of technology and business information. Rapid advances in technology have promoted approaches such as data analytics and more recently Artificial intelligence (AI) which have given organisations in the supply chain much greater visibility and the capacity to improve organisational predictions of consumer and market behaviour. This brings together the concept of lean and agile in a manner which is feasible and cost-effective. However at this stage there are relatively few documented case studies of organisations successfully achieving leagile. Much like the principles of lean and just-in-time, it is an evolving or aspirational target which requires organisations to have an ethos of lean to the effective in the long-term.

3.0 Lean Principles in Operations Practice

3.1 Introducing Lean Processes to Organisations

As the explanations of various aspects of lean, just-in-time, and agile illustrate, the introduction of lean principles and processes in practice is an ongoing strategy. It comprises a number of distinct aspects, and there are various tools that can be used to help an organisation achieve its lean aims. It is also important to note that there are some risks attached to the introduction of lean principles, which have been hinted at previously. These relate to the trade-off decisions which organisations must make as regards the benefits versus the risks of operating with very limited inventory. Supply chains can be relatively easily disrupted if they involve external third parties, and whilst here in the UK we are very familiar with the reliability and quality of our infrastructure, the same cannot necessarily be said of the countries in which some raw materials are produced. This has an impact on the cost and quality of the goods we eventually see in our households, and organisations must decide whether they can afford to pass on such costs, or not have products available. These issues should be discussed by organisations when developing their lean strategy.

In this section we look at the fundamental principles of lean in practice, beginning with a discussion of the types of waste which organisation might wish to try and remove from its operations, and then considering the mind-set or philosophy of continuous improvement. We will also look at a famous technique known as the Toyota Production System (TPS), which, as the name suggests, is accredited to the Japanese automotive manufacturer Toyota. Lean principles generally are said to have emanated from Japan, and it is perhaps helpful to consider Japanese cultural principles when thinking about introducing lean. They focus on the highest quality and efficiency of outcomes, and this is infused within business operations as evident by the TPS. The section concludes with a discussion of some of the challenges of lean, and how an organisation can take practical steps to address these or at least manage them within their operations.

3.1.1 The Types of Waste

There are differing opinions on how many ‘types’ of waste an organisation might have. Current thinking suggests, seven, eight, or even nine depending on the nature of the organisation and the type of work carried out.

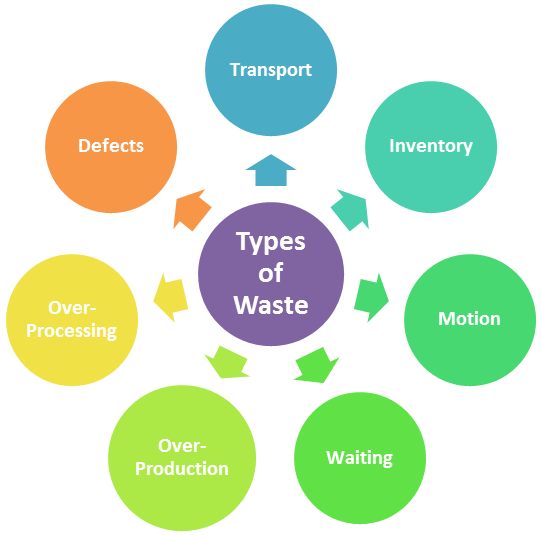

Originally, there were said to be seven types of waste, and these were largely found in manufacturing organisations. They can be listed as:

- Overproduction

- Excess inventory

- Waiting (lost time)

- Unnecessary motion

- Unnecessary transportation (double handling, or moving excess stock)

- Re-work (poor quality)

- Over-processing (over-engineered)

Figure 1 below shows these wastes visually.

Figure 1: Seven Types of Manufacturing Waste (SixSigma.com, 2017, p.1)

In each instance, it is recognised that even incremental improvements can help an organisation to increase its efficiency and reduce its costs. These savings and improvements are typically realised in a greater proportion of better quality output, meaning that even small improvements can have an exponentially large positive outcome.

It is also noted that each one of these types of waste can be tied to different types of organisational or interrelated processes. For example:

- Better inventory management and supply chain management can reduce the need for overproduction and the need to hold inventory, and it is also linked to the principal just-in-time in that there is no need to transport an excessive inventory unnecessarily, nor is there a need to wait unnecessarily for raw materials or component parts.

- From a manufacturing or engineering perspective, unnecessary processing or reworking not only saves time in planning and preparation but also saves cost and resources.

- From an operational layout perspective, a more efficient production line reduces unnecessarily handling unnecessary motion and potentially unnecessary rework.

- Collectively, even small improvements at each and every stage of the process results in outcome known as the accumulation of incremental gains.

More recently there has been discussion of further types of waste, although these are more commonly associated with intangible types of waste suited to service environments. They include the underutilisation of human capital such as a failure for an organisation to be as creative or innovative as possible, and also the waste of underutilised solutions or lost opportunities. This occurs when organisations do not take full advantage of opportunities presented to them because they are constrained by their own measures of success. In other words, an organisation performs well relative to its own targets but because it is introspective it has failed to recognise that its competitors have taken much greater advantage of market opportunities and have much higher standards. In other words, an organisation must be careful it is not measuring the wrong things, and therefore creating waste in the process.

In a world of increasing technological sophistication, it is probable that these latter two wastes, the loss of human intellect and capital, and a lot of opportunities will become much more significant.

3.1.2 Continuous Improvement

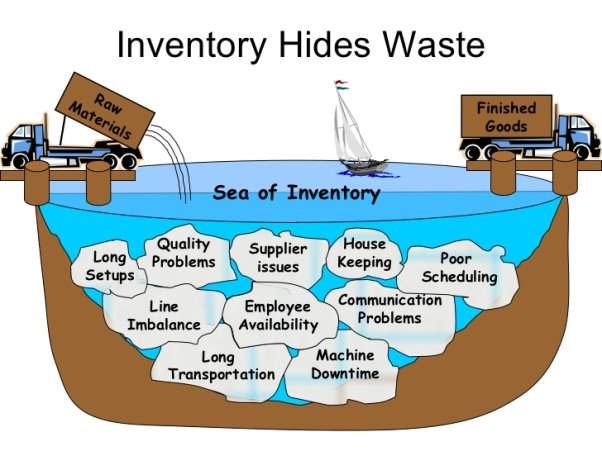

Perhaps surprisingly, very large amounts of waste can be hidden or disguised in organisational processes. Often more so than many organisations may realise because they have failed to update their operational processes for many years. The detail of figure 2 below provides an illustration of some of the types of waste and how they can occur in a ‘sea of inventory’. Therefore, in order to begin to tackle some of the types of waste, identifying these issues and adopting a continuous improvement mind-set can help to reduce and hopefully ultimately eliminate these problems.

Figure 2: Hidden wastes in the Sea of Inventory (Lean Manufacturing, 2010, p.1)

There are a number of practical steps to eliminating waste in basic operations. All of these can be associated with the overarching principles of lean, and the aim of reducing and eliminating waste in operational procedures. These basic working practices are as follows and, the central feature which links all of them is the involvement of everybody within the organisation at every level.

Discipline - well-defined work standards which are adhered to are fundamental to organisational outcomes. Not only does this assist with maintaining quality throughout operational manufacture or process, but it could also have health and safety implications. Everyone must follow these disciplined procedures all the time in order to have the cumulative desired output. A failure to do so, is likely to increase the risk of defects and cost other types of waste in re-work later on.

Flexibility - organisational procedures whilst well-defined, need to accommodate a measure of flexibility. This principle is associated with the natural parameters of a task, meaning that if it is more sensible for different part of the organisation for a different individual undertake the role, then this should be permitted. Ultimately this leads to greater autonomy, and often in practice translates to individuals on the shop floor who are typically very efficient with their jobs, being allowed to adapt (but document or record) more efficient ways of undertaking tasks.

Equality - it is important for organisations to recognise the contribution of every employee no matter what their job role of function in the organisation. Everyone has a job to do, and without full cooperation and collaboration for all employees, then it is unlikely that the organisation will perform well in the long term. Some organisations choose to achieve this by introducing uniform policies irrespective of whether an individual works in a management role or otherwise, or some choose to have open plan offices[1].

Autonomy - there is widespread agreement in other areas of research such as human resources management, that affording employees autonomy in their daily lives dramatically increases their commitment to the organisation and improves their motivation and engagement, as well as their productivity and efficiency. Line managers should have the confidence to delegate as much as possible involving employees in problem-solving on their own account. This however must be tied to principles of flexibility and equality in the sense that organisations must also be willing to accept that are occasions when employees will make mistakes. If organisations then immediately punish autonomous decision-making which doesn't deliver perfect results, then it will immediately inhibit any form of organisational employee engagement. Again it illustrates the point of organisational mind-set.

Employee development - in the long term, an organisation should continue to invest in its employees so that they introduce more efficiency and more creative and innovative suggestions leading to increased efficiency and competitiveness. A highly skilled and highly trained workforce helps to raise the standard within an organisation.

Working quality - also referred to as quality of working life. There is a responsibility on the part of the organisation to create secure working conditions so that employees can focus on doing their job to the best of their ability rather than worrying about aspects such as job security and in the process becoming distracted from their daily tasks. This is particularly pertinent in an era of zero hours contracts as it is shown that there is a direct link between job insecurity and reduced organisational productivity.

Creativity - ideally, an organisation should strive to offer employees the opportunity to work creatively, as this that only increases motivation and work commitment, but also helps to put forward suggestions for improving efficiency and new ways of working which are leaner

Total involvement - if employees are involved in every aspect of the organisation as far as their role and skills permit, they are more likely to be committed to the organisation, and put forward suggestions for organisational improvement. Total involvement also improves internal organisational communication (refer to Figure 2 and lack of communication being a major source of waste). This also helps to increase their creativity and suggestions for improvement.

Overall it can be seen that these working policies are what might be described as best practice and that they are more effective when used in conjunction with one another, valuing the contribution of employees at all levels. Without these fundamental practices in place, it is unlikely that an organisation will see significant productivity improvements. However, it is also obvious that it will take some time for an organisation to implement these policies on the basis that they can be contradictions between organisational discipline and employee creativity. Thus, thinking that these working practices as a long-term aim or goal is perhaps more realistic.

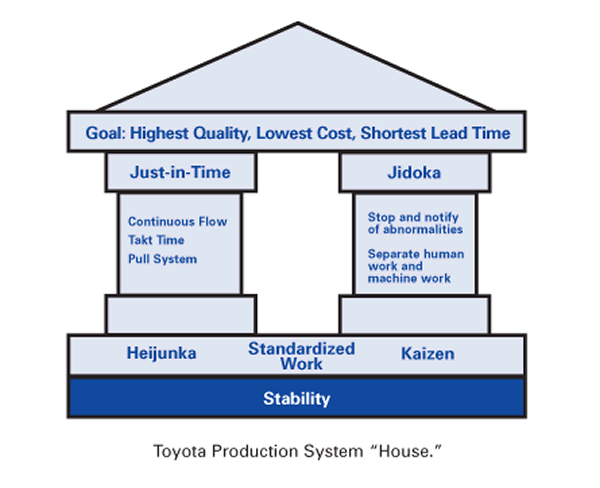

3.1.3 The Toyota Production System

The Toyota production system (TPS) has been described as an integrated approach to just-in-time manufacturing. It brings together two distinct concepts, ‘jidoka’ (roughly translated as automation with a human touch) and continuous flow, or JIT. It originated within the Japanese automotive manufacturer, Toyota, and has now become recognised worldwide as an effective lean manufacturing philosophy. The TPS places people at the heart of the operations, building upon the principle of the basic working practices set out in section 3.1.2 and conceptualised in the detail of figure 3. The wastes referred to in section 3.1 are also said to have originated from the TPS.

The main principle of the TPS is that repetition and experience increase organisational competence and, if this can be further simplified then it increases the robustness of the process. The TPS therefore strives to break down every aspect of the manufacturing process into its distinct component parts, and if possible further subdivided these. For example, using two or three smaller machines rather than one large machine helps to reduce any risk associated with manufacturing breakdown, and also increases flexibility.

Similarly, distributing a task amongst several machines or several people, provided that they are working to the same overarching principles and process controls, can help to increase overall capacity accommodating for bottlenecks and improving process layout and flow. Some of these ideas have been more recently adopted in software for example and software project management where certain tasks are broken down into smaller component parts and operate simultaneously thereby increasing overall efficiency. The key throughout all of this process is to have the communication and transparency to avoid any waste later in the process.

Figure 3: The Toyota Production System ‘House’ (Lean Enterprise Institute, 2014, p.1)

There are also some practical considerations involved with the TPS in terms of the integration of machines, (automation), and people. These focus on a very high level of visibility because the more transparency there is, the easier it is for employees to identify any problems and communicate with one another. Some examples of visibility metrics include:

- Publicly displayed performance measures on organisational noticeboards

- Colour coding systems to identify any problems.

- Control charts which are regularly updated to share progress with all employees

- Highly visible control systems (Kanban and Kaizen - see section 3.4)

- Clear, open plan working spaces

- visible examples of, good and defective products and also competitor products

Within Toyota, they use a colour coding light system known as Andon, when there are any difficulties with any part of the manufacturing process. This immediately stops this small element of manufacturing, and alerts employees to the need to address problems as soon as possible. Toyota recognise that stoppage of a manufacturing line does introduce some inefficiency, but preventing a defect travelling the entirety of the manufacturing line and accruing waste and loss at every stage in the process is more inefficient.

3.2 Possible challenges with Lean principles

Whilst it is tempting to consider the adoption of lean principles as an easy fix organisational inefficiency, there are challenges and criticisms of lean which must be included in any strategic planning. These principally relate to issues of cost and also matters of people and process which, perhaps paradoxically, can significantly inhibit the introduction of lean principles with any measure of effectiveness.

3.2.1 Cost

As will be clear from the explanations in this chapter, the introduction of the principles is neither quick nor straightforward, and involves a very significant organisational change in terms of approach and mind-set. It also, in practical terms, involves cost and investment, something which many organisations can be reluctant to sanction in times of economic challenge. For example, investing in technology to improve the efficiency of machinery, or to gather business intelligence to help make informed organisational decisions.

The use of sophisticated equipment which can self-monitor breakdowns and failures is likely to be expensive, alongside developing bespoke equipment which is subdivided into a number of small parts as opposed to one large machine. Overcoming the long-standing belief that ‘bigger is best’ and economies of scale which arise from this are likely to be expensive.

The TPS, whilst an ideal, also involves planned preventative maintenance of equipment, something which many organisations feel that they cannot afford to do at peak times. The cost involved in changing from a push through to pull through driven operation is likely to be significant, and one which some organisations struggle to justify on the basis that they do not feel that will see an immediate improvement on the bottom line.

Get Help With Your Business Assignment

If you need assistance with writing your assignment, our professional business assignment writing service is here to help!

3.2.2 People and Processes

As described throughout this chapter thus far, there are also inherent tensions between different aspects of lean and just-in-time, especially in terms of people and processes. For example, best working practices involve direct contradictions between process control and allowing employee to demonstrate flexibility and creativity. There are differing opinions of allowing autonomy and yet conforming to establish organisational procedures. Current trends for flexible and adaptive working and so-called zero hours contracts, directly undermine the principles of job security but are justified on the basis of improved bottom line effectiveness.

It is quite likely in practice that attempts to introduce lean mind-sets will meet with organisational resistance, particularly if it is likely to involve significant disruption even the loss of particular organisational departments. Moreover, although the TPS places people at the heart of organisations, it must be remembered that this mind-set was developed in a different national cultural setting, and it does not always translate easily to other cultures. This is evidenced for example in the directly contradictory views as regards open plan offices. Some arguments suggest that they increase efficiency, collaboration and cooperation because employees can quickly and easily talk to one another without barriers. However, other research studies from other disciplines suggest that open plan offices reduce efficiency because they disrupt the working patterns of some employees, result in wasted time gossiping rather than working, and increase employee ill-health and stress. What open plan offices might be cost-effective, some critics suggest that arguments put forward in support of open plan offices were in fact driven by cost considerations.

The trouble with these contradictions is that the overarching lean philosophy does not fit well with organisations picking and choosing which parts of lean they would like to use. It creates obvious challenges in terms of successfully developing and lean strategy and introducing it within an organisation over time. It is also likely to be more difficult for long-standing organisations with well-established principles and manufacturing processes which may not themselves be easy to adapt and update. All of these challenges need to be considered when identifying how lean can be introduced.

4.0 Kaizen and Six Sigma

4.1 Kaizen

Kaizen is broadly interpreted as the Japanese term for continuous improvement, although it is perhaps more accurately translated as a form of control. It applies to all aspects of organisational output, and can thus be linked to both TPS and types of waste, as well as the means of introducing and managing basic employee working conditions. One of the most popular tools of Kaizen is a Kanban, which of itself translates to differing types of organisational process control, which collectively lead to greater organisational production efficiency.

The overarching principle of Kaizen, and Kanban within that, is to create a ‘pull through’ organisational process, as opposed to push through. Historically, for many manufacturing organisations, understandably, they would place the manufacturing process itself at the heart of operations, and would strive to make this element as efficient as possible working towards metrics such as overall equipment efficiency. In practice this typically translates to producing as much as possible as quickly as possible because it reduces individual unit cost. It is an example of the cost / efficiency trade-off in practice. Understandably, employees involved in manufacturing will work towards achieving their efficiency targets if this is what they are encouraged to do, giving no thought to wider impact and the production of waste in the process.

To illustrate, working on producing widgets at the lowest possible unit cost by mass-producing them as quickly as possible, not only results in waste in terms of overproduction (refer to section 5.2) but also waste in terms of unnecessary inventory, unnecessary transportation, and unnecessary storage. By driving overall processes from one single manufacturing point, an organisation may well meet its targets, but not only is likely to be ignoring what the competition is doing, it is not even listening to what customers are asking for (a lost opportunity or waste #9). In the long term this could result in obsolete stock which is also very costly and wasteful.

To reach the process of continuous improvement, therefore, a degree of control is necessary which accommodates some measure of apparent inefficiency in different parts of the organisational process to give overall greater production and supply chain efficiency. Much like the principle of Andon, where Toyota recognise that a small degree of inefficiency in one part of the production line is better than waste throughout the entirety of the production line, balancing efficiencies with sensible organisational control metrics is much better in the long term. It can be, however, a very challenging way for organisations to think unless they are familiar with the process. This is why we talk about lean being a philosophy as much as a set of actions or behaviours.

4.1.1 Kanban

A Kanban is a way of controlling organisational procedures. It typically controls the flow of inventory through an organisational process. In some ways it can be seen as deliberately limiting, but the idea behind Kanban is that an organisation only works with what it needs to, no more and no less. This reduces clutter and unnecessary inventory, increases transparency, and reduces the various types of less obvious waste such as those hidden in the sea of inventory (figure 2).

Various types of Kanban signal the movement of goods through the process, and examples are likely to include movement of component parts to the next stage in manufacturing, or calling for raw materials to begin the process of manufacturing. Some organisations choose to deliberately and physically inhibit the opportunity for holding inventory by significantly reducing stock holding capacity. In a retail example, small city centre shops, such as express supermarkets, often hold little to no inventory other than what is on sale on the shelves. When it is sold it is gone and there is no replenishment until the following morning, but this prevents any form of food waste. It also means that as much of the costly city centre retail space is available for generating profit from sales rather than serving as a very expensive form of short-term warehouse.

Other types of Kanban might include those outside of the organisation, for example signalling to vendors or suppliers that it is time to replenish stock or raw materials. This is now often possible with software such as Vendor Managed Inventory (VMI) whereby there is transparency between the retailer and supplier as to accurate real-time stock levels which trigger the next delivery and order point on an automated basis. EPOS (Electronic Point of Sale) is another way of achieving this, when suppliers update their own order records on the basis of scans barcodes at the point of sale. This provides accurate real-time information of consumer demand and drives a pull through supply chain, thereby reducing unnecessary waste in the process of ordering, and preventing organisations from ordering stock which they may not be able to sell.

4.2 Six Sigma

Six sigma is a more sophisticated and complex approach to reducing waste in operational processes, and is typically only found in high-level volume driven manufacturing. It is the practice of using statistical techniques to identify quality defects, and make appropriate corrections in order to eliminate such quality defects and eventual waste and costs that they cause. The principles of six Sigma stem from kaizen, and they are distinct not interchangeable. Likewise, the terminology lean six sigma is an amalgamation of principles not a distinct construct in its own right. Examples of six Sigma in practice are more often found in critical manufacturing processes, such as the manufacture of pharmaceuticals. Any quality defects in this process are likely to have very serious consequences, and so it is vitally important that there is a lot of focus on quality control and much less tolerance for any degree of quality failure. Six sigma can be highly effective in this environment ensuring exceptionally high consistent levels of quality manufacturing output. It is, however, a complex and costly way of measuring organisational production quality involving large-scale analysis and sophisticated data interpretation. The cost of engaging in this process in itself is notable, but in the case of pharmaceuticals for example, is likely to still be significantly cheaper than managing lawsuit arising from substandard pharmaceuticals reaching the marketplace. In the case of manufacturing a paper plate or plastic bag, then the cost of introducing such extensive quality control principles are less likely to have trade-off benefits, once again illustrating the fundamental principles of operations management organisations must themselves decide what constitutes an acceptable level of risk and what cost they are prepared to pay to eliminate or reduce this risk.

Get Help With Your Business Assignment

If you need assistance with writing your assignment, our professional business assignment writing service is here to help!

5.0 Chapter Summary

This chapter has focused concept of lean production explaining the fundamental principles of lean, and the related concepts of just-in-time and agile, as well as the TPS, Kaizen and Kanban. It has addressed the basic elements of organisational waste, explained what they are and how they can be reduced and eliminated, and also illustrated the interrelationship of operations management principles, highlighting the ongoing potential tension between different aspects of lean principles and the practicality and reality of operations management. Reference has also been made to more sophisticated aspects of lean such as six Sigma which work more effectively in some types of organisational operations than others. The key message to take from this chapter is that lean is as much of an organisational philosophy as it is a set of tangible principles to apply, and that the organisation must, if seeking to apply the principles, have a clear long-term strategy and a measure of patience in introducing lean principles, as some of the benefits are likely to take time to become apparent. However, when they do, these benefits are likely to be significant.

6.0 References and Further Reading

6.1 References

Lean Enterprise Institute (2014) The Toyota Production System House [online] available at https://www.lean.org/lexicon/toyota-production-system retrieved 5th Sep 2017.

Lean Manufacturing (2010) Waste of Inventory - Causes [online] available at http://leanmanufacturingtools.org/106/waste-of-inventory-causes-symptoms-examples-solutions/ retrieved 5th Sep 2017.

SixSigma.com (2017) Seven Types of Waste [online] available at http://www.whatissixsigma.net/seven-types-of-waste/ retrieved 5th Sep 2017.

Slack, N., Brandon-Jones, A., Johnston, R. (2013). Operations Management, 7th Edition, Harlow: Pearson Education Ltd.

6.2 Further Reading

Andersson, R., Eriksson, H., and Torstensson, H., (2006) Similarities and differences between TQM, six sigma and lean. The TQM magazine, 18(3), 282-296.

Antony, J., (2011) Six Sigma vs Lean: Some perspectives from leading academics and practitioners. International Journal of Productivity and Performance Management, 60(2), 185-190.

Inman, R. A., Sale, R. S., Green, K. W., and Whitten, D., (2011) Agile manufacturing: relation to JIT, operational performance and firm performance. Journal of Operations Management, 29(4), 343-355.

Monden, Y., (2011) Toyota production system: an integrated approach to just-in-time. Boston: CRC Press.

Ohno, T., (1988) Toyota production system: beyond large-scale production. Boston: CRC Press.

Singh, C. D., Singh, R., and Singh, S., (2013) Application of lean and JIT principles in supply chain management. International Journal of Management Research and Business Strategy, 2(1), 85-98.

Sugimori, Y., Kusunoki, K., Cho, F., and Uchikawa, S., (1977) Toyota production system and kanban system materialization of just-in-time and respect-for-human system. The International Journal of Production Research, 15(6), 553-564.

7.0 Chapter Case Study

Williams Construction is a medium-sized manufacturing firm producing and supplying items for the construction industry. These range from items necessary for large-scale construction such as scaffolding and support items through to small component parts such as nails and screws. They also operate as a reseller for construction tools such as saws and screwdrivers amongst many others. They are located in a semi-rural but relatively affluent area and have been established for over 20 years having a good reputation in the marketplace for being able to supply whatever it is that local craftsmen and contractors need.

As construction items to not have shelf life, relatively little consideration has ever been given to the importance of managing inventory. Provided that there is space to store the items, then the situation of holding large amounts of miscellaneous stock has been allowed to continue. As the firm's focus is primarily offering high levels of personalised customer service, little thought is given to obsolete stock or the very significant costs of storage. Similarly, no thought has ever been given how to improve the efficiency of manufacturing or the manufacturing process overall.

The next generation of the family are due to take over the business, and the upcoming managing director has come across an article discussing the value of lean principles. He is especially keen to try and introduce some of these principles within Williams Construction, but recognises the scale of the task that faces him and is unsure where to begin. He is also concerned about upsetting long-standing employees and customers as change has never in the past been a feature of Williams Construction. However, the forthcoming MD has ambitious plans to expand and believes that it will be possible to generate significant efficiency gains and therefore release capital to invest in expansion.

You have been hired by Williams Construction to provide an initial analysis of the manufacturing and stock-keeping procedures and also provide an indication of how you would begin to introduce lean within the organisation. Using your experience of operations management and particularly lean and agile approaches, provide a short executive report outlining the main points to consider and your initial suggestions for introducing lean. Make sure to address all aspects of the lean process with particular emphasis on the inclusion of employees and involvement in the lean process. Within your report, draw up a list of questions which you would ask of key employees within the organisation to understand in their opinions of working processes as they stand.

[1] Some caution is now advised with the latter for two reasons. First, open plan offices have been shown to reduce productivity for some employees because of the noise and disruption and also ill health arising from having many people together in a small constricted space. Second, it can be also considered as discriminatory for individuals who have autistic spectrum disorders and open plan offices make them ill - individuals with autistic spectrum disorders, however, are shown to be very productive in other ways. This highlights the importance of organisations thinking about their lean principles holistically and adapting processes to suit organisational needs.

Cite This Module

To export a reference to this article please select a referencing style below:

Related Content

CollectionsContent relating to: "Business Management"

Business Management describes the management of business operations and activity, including the planning, organisation, resource allocation, and implementation of efforts towards achieving their goals.

Related Articles

Strategic Business Management and Planning Coca cola Company

In the exact of science Business planning is often described as more than of an art. In organizations this becomes especially true when ones business plans revolve around the cycle of annual budgeting...

STRATEGIC BUSINESS MANAGEMENT AND PLANNING OF NESTLE

INTRODUCTION: – Nestlé was founded in 1866 by Henri Nestlé and is today the world’s biggest food and beverage company. Sales at the end of 2005 were CHF 91 bn, with a net profit of CHF 8...

Operations Management Lecture Notes

This chapter focuses on key concepts in operations management. In the words of Slack, Brandon-Jones, Johnston and Betts, (2012, p.4)......

GBR

GBR